Exploring Smart Manufacturing in the Detroit Region

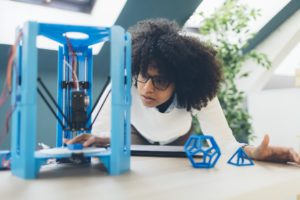

Example of smart manufacturing.

CLUSTER INTRO: The Detroit Regional Partnership’s (DRP) seven-industry cluster program received the C2ER Research Award for Project Impact in its first year. In keeping with current industry trends, data for each cluster is being updated and re-launched on the DRP website. The Detroit Region is a world leader in innovating how goods and products are made, leading the integration of new technology into advanced manufacturing. Serving as a top smart manufacturing hub that’s powered by high-skilled talent and a vast business network from traditional manufacturing, ”Industry 4.0” and more throughout the 11-county Region. Here’s a peek at the latest findings.

Smart Manufacturing Talent: Overall the Detroit Region is one of the densest locations for manufacturing related talent, having more than 253,000 manufacturing industry jobs in 2021.

- Detroit ranks #1 metro in the U.S. for total assembler and production talent with more than 201,000 jobs in 2020. The Region is not only notable for having a large talent base, but also having talent that’s hard-working and skilled, assembler and production talent in the Detroit Metro has one of the lowest talent turnover rates (52%, U.S. average is 75%) in 2020.

- Detroit Ranks #1 for total of tool & die makers in the U.S. and one of the densest locations, Michigan has nearly double the talent then the next state, with 9,800 jobs in 2021.

- Detroit is the #2 U.S. metro for total plastics manufacturing talent there are more than 31,000 plastics manufacturing jobs, 2021.

Why the Region is Ideal for Smart Manufacturing: (Source: DRP, Research America Smart Manufacturing Survey from 2020)

- Access to the supply chain, exceptionally large auto, aerospace and defense clients

- Understanding robotics with high quality and volume production capabilities

- Innovative technology integration with the workforce to support the infrastructure

- Deep rooted talent and knowledge in smart manufacturing and lean principles

- Proximity to businesses, customers and key markets in a low disaster hazard area

- Near natural resources and fresh water, ideal for cooling in processing advanced materials

Case Study: Yanfeng, Advanced Manufacturing Plant

In 2020, the new Yanfeng facility in Highland Park, Michigan underwent a complete $30 million redesign of its manufacturing plant, which assembles automotive interior components, including cockpits, floor consoles and door panels. This included an expansion of employees which exceeded their initial goal by currently employing 675 at the retooled state-of-the-art manufacturing plant. Yanfeng has eight technical centers and plants in Michigan, including its North American headquarters in Novi. In total, the company employs more than 3,700 people in the state of Michigan, its largest talent cluster in the United States.

Smart manufacturing and diverse talent.

- “At Yanfeng, all eyes are on Highland Park as we launch innovative automotive interior components. This plant represents a significant investment for our company in the region and is a benchmark facility in our network. Michigan is essential for us and offers top-tier talent as we send just-in time parts deliveries to our customer” – Tony Elenbaas, Vice President & General Manager, North America for Yanfeng.

- YouTube Link: https://www.youtube.com/watch?v=2Ye5fTikA7o&feature=youtu.be

Business Case PDF: https://info.detroitregionalpartnership.com/smart-manufacturing-pdf

Story Map: https://info.DetroitRegionalPartnership.com/smart-manufacturing-story